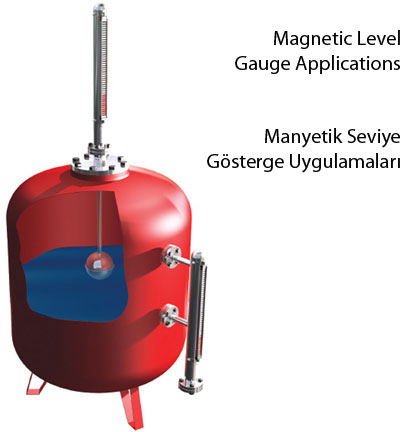

KRS-137 Level Gauge

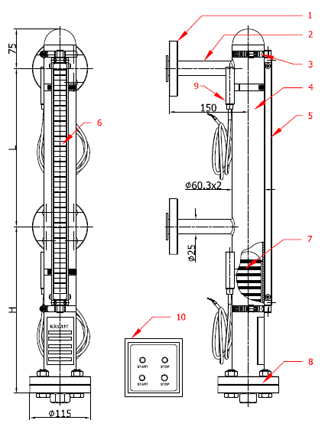

Big Switch Type

Magnetic level gauges are installed in the tanks in various ways, where it is supposed to measure the level of the liquid. The floater in the by-pass tube moves up and down with the fluid based on the principle of communicating vessels. The movement of the floater makes the bi-color magnetic

disks placed in the aluminum profile to rotate around themselves. The magnet in the floater is situated at the same level as the liquid regarding the immersion depth of the floater. Thus the bi-color magnetic disks, which colors visible from outside are changed by the floater, indicate the liquid level exactly and precisely. The color of the magnetic disks, as seen from the outside, begins to turns to red when the liquid level ascends, and conversely turns to white when it descends. In this way the liquid level in the tank can be monitored correctly. Magnetic level gauges can also be used in automation systems as a data input device. The liquid in the tank can be monitored by height of the liquid level, the volume of the liquid in the tank, etc. Using switches equipments like pumps, solenoid valves, etc can be controlled. The information of liquid level can be transmitted to the automation systems by connecting a series of reed-switches and control panel hardware to the magnetic level gauges.

Lower Spacing

H=Float Length- 10 mm

Flange Center Spacing

L=150 – 5500 mm.

Design Features

Design Pressure : 25 BAR

Design Temperature : – 40 + 300 C

Usage Area

- Chemical Storage Tanks

- Steam Boilers

- Gasoline Tanks

- Undereground Tanks

- Acid Tanks

Advantages

- Continuous & Easy Monitoring

- A Leakproof Design

- Flange Connection In International Norms (ANSI,DIN etc.)

- Operational with various medias.

- High Temperature & Pressure Resistance

- Long Lasting

Media

- Petroleum Produtcs

- Water, Wastewater, seawater

- Acids

- Gas (As Liquid)

- Caustic Materials

- Foam (As Liquid)

Flange Connection : DN 20 PN16 St 37.2

Connection Pipe: AISI 304

Pipe Clamp : AISI 304

Bypas Pipe : AISI 304

Display Roller Unit : Alüminium

Magnetic Rollers : Temperature Durable Special Plastic

Float : AISI 316 L

Bottom Discharge Flange: St 37.2

Switch: AISI 304 Tube 2mt cable

Control Panel: Plastic

Special Note

Carbon steel parts of all magnetic level gauges are cadmium-plated. Products are under our 2 years quarantee for factory faults. For special requirements please consult us. Please see Useful technical tables pages for flange and pipe size tables. Pleasee consult us for abrasive medias.

Some Possible Errors and Solutions

Fluid level appears white instead of red

Since the indicator panel has been installed in reverse, the fluid level appears in the wrong color. Solution: Remove the indicator panel, rotate it 180 degrees, and reinstall it on your device. This will resolve the issue

Incorrect fluid level display

-

The float may be dirty or stuck in fluids with high density.

Solution: Remove the float, clean it thoroughly, and reinstall it. -

The float may have become stuck due to solid particles in the tank entering the bypass tube.

Solution: Remove the float, clean any foreign matter inside the tube, and reinstall it. -

The float may be damaged or malfunctioning.

Solution: Replace the float and install a new one. -

The float may have been inserted into the bypass tube in the wrong orientation.

Solution: Adjust the float according to the direction indicated by the arrow and reinstall it properly.

No variation in fluid level is observed in the tank where the device is mounted.

-

The float is missing.

Solution: Install the float. -

The float may be dirty or stuck in fluids with high density.

Solution: Remove the float, clean it, and reinstall it. -

The float may be stuck due to solid particles in the tank entering the bypass tube.

Solution: Remove the float, clean any foreign matter inside the tube, and reinstall it. -

The float may be damaged or malfunctioning.

Solution: Replace the float with a new one. -

The float may have been inserted into the bypass tube in the wrong orientation.

Solution: Adjust the float according to the direction indicated by the arrow and reinstall it correctly. -

The discs in the indicator profile may be stuck or overtightened with clamps.

Solution: Install them properly according to the instructions in the user manual.