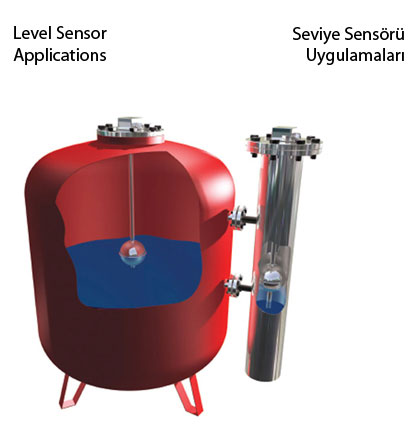

KRS-123 Level Sensor

Threaded Type With Switch

Level sensors consist of a stainless steel floater sliding along a stainless steel pipe, and various control panels. They can be manufactured at various lengths in accord with user requirements. The working principle of magnetic level sensors can be summarized as follows: Reel-switches having been placed in the stainless steel pipe are stimulated by the magnetic floater, and this stimulus is transmitted to the control panels.

Equipments like pumps, solenoid valves, etc can be controlled with these signals. In addition to these, the change of the liquid level in the tank can be monitored through the digital display as %, liters, etc. by transmitting these signals to the digital control panels, and to the automation system via 0-10V or 4-20mA analog the interface.

Pipe Length

L=300 – 6000 mm.

Design Features

Design Pressure : 10 BAR

Design Temperature :– 10 + 150 C

Usage Area

- Chemical Storage Tanks

- Steam Boilers

- Gasoline Tanks

- Undereground Tanks

- Acid Tanks

Advantages

- Continuous & Easy Monitoring

- A Leakproof Design

- Flange Connection In International Norms (ANSI,DIN etc.)

- Operational with various medias.

- High Temperature & Pressure Resistance

- Long Lasting

Media

- Petroleum Produtcs

- Water, Wastewater, seawater

- Acids

- Gas (As Liquid)

- Caustic Materials

- Foam (As Liquid)

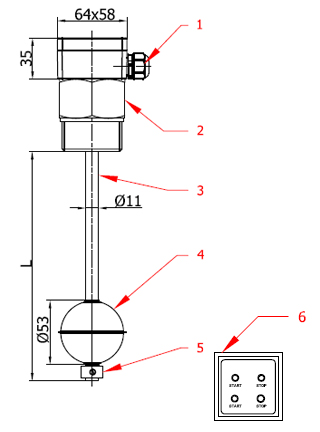

Terminal Box : Aluminium

Theraded Connection : 2″ BSP St37-2

Tube : AISI 304

Float : AISI 304

Float Fixed: AISI 304

Control Panel: PVC

Special Note

Carbon steel parts of all Level Sensors are cadmium-plated. Products are under our 2 years quarantee for factory faults. For special requirements please consult us. Please see Useful technical tables pages for flange and pipe size tables. Pleasee consult us for abrasive medias.

Liquid Densities

| Media | Temperature °C | Density kg/m | Media | Temperature °C | Density kg/m |

|---|---|---|---|---|---|

| Acetone | 25 °C | 784.58 | Hexanol | 25 °C | 654.83 |

| Alcohol, ethyl | 25 °C | 785.06 | Isobutyl alcohol | 20 °C | 801.60 |

| Alcohol, methyl | 25 °C | 786.51 | Kerosene | 60 F | 817.15 |

| Automobile oils | 25 °C | 880-940 | Linseed oil | 25 °C | 929.07 |

| Benzene | 25 °C | 873.81 | Methanol | 20 °C | 791.30 |

| n-Butyl Acelate | 20 °C | 879.60 | MEK | 25 °C | 802.52 |

| n-butyl Alcohol | 20 °C | 809.70 | Milk | 15 °C | 1020-1050 |

| n-Butyl Chloride | 20 °C | 886.20 | Naphtha | 15 °C | 664.77 |

| Carbolic acid | 15 °C | 956.30 | Napthalene | 25 °C | 820.15 |

| Coconut oil | 15 °C | 924.27 | Octane | 15 °C | 917.86 |

| Cotton seed oil | 15 °C | 925.87 | Olive Oil | 20 °C | 800-920 |

| Crude oil 32.6 API° | 60 F | 862.00 | Propylene glycol | 25 °C | 965.27 |

| Diesel fuel oil 20 to 60 | 15 °C | 820-950 | Pyridine | 25 °C | 978.73 |

| Dimethyl Acetamide | 15 °C | 941.50 | Rosin oil | 15 °C | 980.00 |

| Ethyl acetate | 20 °C | 900.60 | Sea water | 25 °C | 1025.18 |

| Ethyl Alcohol | 20 °C | 789.20 | Soya bean oil | 15 °C | 924-928 |

| Fuel Oil | 60 F | 890.13 | Sunflower oil | 20 °C | 920.00 |

| Gas Oils | 60 F | 890.00 | Styrene | 25 °C | 903.4 |